I’ve been slow to come up to speed on the radio front since we’ve moved here. Until March 2017 we were bouncing back and forth between Phoenix and Colorado Springs, furiously working on both houses, one to sell, and the other to live in. Given that I was trying to write a new novel during that time (and was now in my mid 60s) time was tight and personal energy scarce. But more to the point, I wanted to do it right. Most of the trouble I had with my station when we lived here in the 90s was a lousy ground system. A year or so ago I took the time and built a Bentonite ground with a water pipe down the full depth of the Bentonite to keep it wet, ideally with Epsom salts in solution. The ground rod is right next to the entry box through which all my cables go through the wall of the small garage where my station is.

With the ground in place, I strung 75′ of #16 solid copper between one of my two big palm trees and the mast on the roof of the garage, where the TV antenna used to be. On the mast I mounted my venerable Icom AH-3 autotuner. I had to make an extension cable for the control line, which was only 16 feet long, but the cable path was close to 30. The antenna was finished and in place, in fact, a few weeks prior to getting the entry box mounted. Once I got the coax, ground, and control cables into the garage, I took a break (it was a hot job up there on the roof in the actinic Arizona sunlight) and came back after supper. Fired it up and everything worked like a champ. Worked a guy in Colorado, called it victory, read for an hour, and collapsed into bed. Didn’t get back to the station until the next day.

So late morning I turned everything on, selected 20 meters, and pressed the Tuner button on the front panel of my IC-736.Tink! The rig’s meter needle slammed against the high peg. Whoa. Didn’t do that last night. I tightened all the cables, ran up the ladder to look at the mast setup, and tried again. NFG. I checked the cables for shorts, re-checked all the connections to the ground bus inside the garage, but no joy. I let it set and went back to my office to get some words in on Dreamhealer. That night after supper I went back out there and tried the tuner. Shazam! Everything worked! I didn’t hear much traffic, sunspots being what they weren’t, but the AH-3 tuned my longwire and the IC-736 was happy. I worked a couple of guys and heaved a sigh of relief.

The next day I bopped back into the shack after an hour or two writing, and scanned the bands to see what was live. Heard very little on 20m. Switched to 40. Hit the Tune button. Tink!

I was starting to see a pattern: Works at night. Craps out during the day. Hmm. I opened up the tuner and saw nothing obviously amiss. That said, I had bought the AH-3 in 1992, and it had spent the rest of the 1990s out in the sun, matching my 180′ longwire, lousy ground notwithstanding. It got plenty hot during the day, and I worked plenty of stations all day, irrespective of temperature. Alas, electronics don’t live forever.

I did try a few things. I modified a cardboard moving box into a sunshield and placed it over the tuner so that the bottom of the box faced south and the flaps taped open. The AH-3 was thus shaded entirely but still open to the air. On a whim I put the sensor unit for our wireless thermometer inside the box with the tuner. With the carboard box in place, it worked for a little while longer–maybe another hour–after full sun hit the box. I did a lot of testing and temp recording over the next day and a half. Results: It worked until the air temp hit ~90F. Then, Tink!

Hell, I’ve been a ham now for 46 years. I fix things. I used to fix things for a living, in fact. But at some point I realized that troubleshooting an intermittent 28-year-old tuner was becoming a bad use of my time. Icom had released a newer but compatible tuner ten or twelve years ago. I found a place online selling NOS AH-4s at a discount (Gigaparts in Las Vegas, if you’re interested) and ordered one.

The AH-4 is a little over half the size of the AH-3. I still had to make a custom control cable, but with that done it works like a champ, even in the noonday sun. Granted, it’s not summer here anymore. We’ll see how it performs next June. But in the meantime, I have 75 feet of wire working against a good ground. A guy can do a lot with that alone.

I do intend to get a vertical for the higher bands. The longwire will remain for 40, 80, and 160. (The AH-4 tunes the wire easily on 160. The AH-3 had trouble sometimes, even during the night.) My (not yet purchased) vertical will be ground-mounted close to the ground rod. If I need a few radials I’ll throw them in. At that point the antenna farm will be mostly complete. I have a VHF discone but I also want a 6-meter vertical somewhere, and there’s more thinking to be done about what goes where.

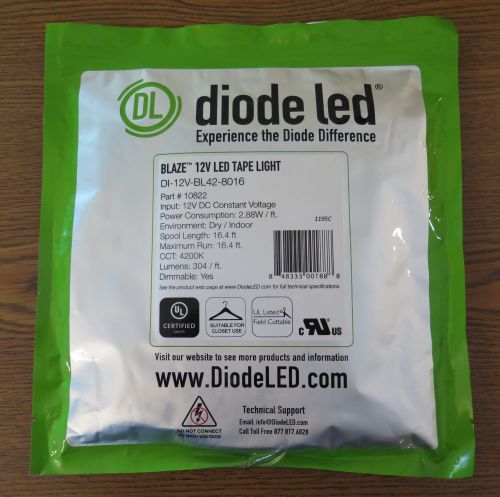

My other ham radio project is still incomplete: An uninterruptible 12V power supply system to run my IC-729 mobile HF rig and shack lighting. With AC power, the panel will draw on a 30A 12V supply I built back in the 1990s. If mains power drops, power will automatically switch to a battery supply of some sort. Near-term, probably gel cells trickle-charged off mains power. Ultimately I want to put a couple of panels up on the roof and buy a husky lithium-ion pack like those sold by Goal Zero. More on that as it happens. It’s the first time I’ve ever used Anderson PowerPole connectors, about which I have mixed feelings. But like everything else in electronics, the journey is the education, and the results are the reward. This time it’s been slow coming together, but better slow than never.

More as it happens.

I had done the math on the volume of the hole and the density of bentonite clay, and calculated that I would need four 50-pound bags of bentonite powder. I bought it from a drilling supplies firm on the west side, for $8 a bag. (Bentonite has many uses, and one common use is borehole mud.) Some people mix a bentonite slurry in a wheelbarrow and then tip the slurry into the hole, but I didn’t have a wheelbarrow. What I did is fill the hole by pouring in a layer (3″ or so) of bentonite powder, and then wetting it with water in which I had dissolved ten pounds of Epsom salts. I stirred the goop a little with a metal rod to make sure all the powder got wet.

I had done the math on the volume of the hole and the density of bentonite clay, and calculated that I would need four 50-pound bags of bentonite powder. I bought it from a drilling supplies firm on the west side, for $8 a bag. (Bentonite has many uses, and one common use is borehole mud.) Some people mix a bentonite slurry in a wheelbarrow and then tip the slurry into the hole, but I didn’t have a wheelbarrow. What I did is fill the hole by pouring in a layer (3″ or so) of bentonite powder, and then wetting it with water in which I had dissolved ten pounds of Epsom salts. I stirred the goop a little with a metal rod to make sure all the powder got wet.