We replaced nearly all of the incadescent bulbs in the house with LED bulbs shortly after we bought it in late summer 2015. That came to 27 60W bulbs and ten or twelve 75W floods for ceiling can lights. You can’t get incandescent bulbs in the commoner sizes anymore, and the power savings is considerable. LED bulbs have come a long way in the last few years, and the “softer” light quality levels (3000K and below, most of which were 2700K for us) approximate incandescent light close enough for what we do.

There are a couple of issues with LED bulbs. We bought Feit bulbs in bulk when we re-bulbed all the ceiling fan lights. Two years on, and the Feit bulbs are dropping like flies. I have nine dead but intact Feit 60-watters on my workbench, and two more that I dismantled to see what’s in them. What’s in them isn’t much: A voltage doubler/rectifier board that converts 117VAC to 236 VDC. There’s a disk holding nine LEDs, with two wires down to the power supply. The photo above shows what it looks like when you hacksaw the plastic globe off a Feit 60W equivalent LED bulb. It’s unclear to me whether the nine LEDs are single diodes or blocks of several fabricated together. It seems like a stretch to put 26 volts on a single LED and not see it emit plastic instead of light.

I’ve been taking bulbs apart to try and see why the Feit bulbs die so young. I’ve pulled two apart: One had a bad power supply. The other had a bad wafer. The wafer, however, was intermittent: Tap it with a screwdriver and it flickers, and sometimes comes up to full brightness. The dead power supply was just dead, without any indication of why. It stayed dead when tapped, unlike the intermittent wafer. Cheap crappy manufacturing, I’d guess. This is one Feit I will gladly walk away from.

LED lighting is problematic in ham radio work because of the broadband noise generated by the bulb power supplies. Fluorescent tubes have the same general problem. My notion is to create a separate lighting system in my workshop/ham station using LED lamps run straight-on at 12VDC. I had hoped that the wafers ran at 12VDC or 24VDC, so that I could harvest them from bulbs with failed power supplies. Not an option.

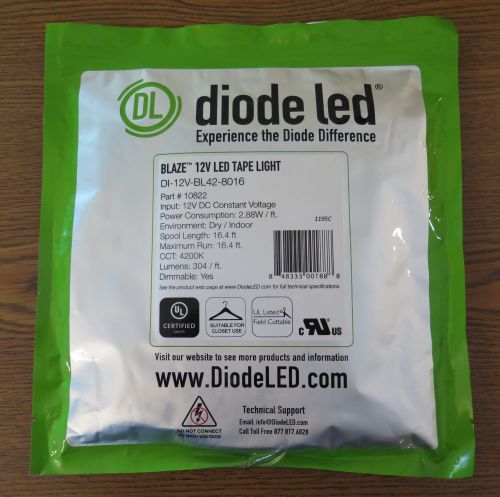

So I started sniffing around to see what sort of lamps are available for 12VDC. I bought a couple at a hamfest to play around with, and talked to the techs at a lighting store up in Kierland. They had an interesting display: Assemble-it-yourself LED strip lights. These consist of an anodized aluminum U-channel, with a self-adhesive strip of LEDs stuck to the bottom of the channel, with a linear plastic lens that snaps into the U-channel. The LED strips take 12VDC, and use 2.88W per foot.

The LED tape strips come on a reel, with 16.4 feet on the reel and 3 LEDs per inch. The reel isn’t cheap; I paid $235 for it, and that’s about what they go for on Amazon. What I did was buy an 8′ section of channel/lens and put down just under 8′ of LED strip. The strips have clearly marked points every inch where you can cut them with an ordinary scissors, leaving solder pads on each side of the cut.

The strip comes with a .215″ female barrel connector on the end of 6′ of 2-conductor cord. But again, there are solder pads every inch, so you can wire them to a power source any way you want to. What I did (at least for testing) is dig around in my Big Box o’ Wall Warts and found a Dell APAC-1 power supply, which came with a Dell matrix printer someone gave me ten or twelve years ago. It’s labeled for 12VDC @ 2A, and the strip draws 1.92A, so the supply is working pretty hard. (It squeals, way up there where Carol can hear it and I can’t.)

What I did with the strip is mount the four clips that came with the U-channel under the front edge of the first shelf above my workbench, and then clipped the U-channel to the shelf. The lower surface of the shelf is 11″ above the bench, so I’d have to do some bending and stooping to actually see the LEDs. And the intensity of the light is marvelous, shining down right where I do the sort of close work that electronics requires, which these days is real damned close.

Because the light comes from a strip of 288 LEDs, there are basically no shadows anywhere under the strip, unless you completely block the light. This means that you can work in good light without worrying as much about your hands casting shadows on what you’re doing. It’s almost like the project photos in old QSTs, where all parts of a complicated hand-wired chassis are completely illuminated. The photo below is of a high-voltage power supply placed on the bench beneath the LED strip, and is literally what you’d see were you sitting at the bench poking at the supply.

This was only a first step. The strip won’t be powered by the APAC-1 long-term. I have a 30A 12VDC supply that I built out of an old minicomputer power supply somebody gave me. That will be the power source for all the lighting in my workshop/shack once the whole system is complete. I’m looking into overhead lighting now, and may simply use the remaining 8′ of LED strip on the reel with a white diffuser lens, clipped to the drywall ceiling.

Ultimately I want to work up a solar panel system on the roof of the garage, charging a 12V battery of some sort to supply lights and radios. The landscapers are going to auger a hole next to the shack for an engineered ground system tomorrow morning, so I have other work to do before I get on the air. It was a fun project, and will make working on projects a great deal easier. Good light is not optional!